"Fashion is not something that exists in dresses only. Fashion is in the sky, in the street;

Fashion has to do with ideas, the way we live, what is happening." - Coco Chanel"

Shirtmaking Begins

Sewing for my daughter is lots of fun. Not just because I get to sew something and it happens to be for her… there is a whole lot of stuff that happens. There is the choosing of the pattern and fabric that gives us the opportunity to spend some time together. And then there is this communicative thing that happens between us. We talk about our likes and dislikes, our favorite colors, what trends we like and what we absolutely hate! We talk about what looks good on her and what looks good on me. She becomes my confidante/fashion apparel assistant adviser. And in all of this, the mother-daughter bond is ever strong (most of the time). So.. how do I improve the bonding power in my relationships with my sons using the sewing approach? Easy! By shirtmaking (hopefully).

Unless one is fortunate enough to have a shirtmaker mentor, you will be forced to start off like I did and visit your local fabric store, looking through the pattern books hoping there is a men’s pattern available. I did find one that I thought I could live with.

McCalls 6044 I could live with him. Hey! I’m human.

I could live with him. Hey! I’m human.

Ahem…My shirtmaking career is going to start with my first victim, Jared, so I selected an x-large pattern size because that’s what he wears in RTW (ready-to-wear) shirts. Now I know better than to think that this shirt is going to be an exact fit so before cutting out anything, I decided to get lots of measurements. First of course were my son’s. The next were from a shirt that fits him comfortably. I measured the neck, the shoulder length, the armhole (armscye), shoulder width, chest, waist, hips and shirt length.

The pattern measurements were almost identical to the RTW shirt so I figured I would push on to making a muslin (with a little tweek of course). I wanted a traditional yoke in the back, not a western styled one that comes with the pattern so I changed it. The result… well the neck fit really nice, but from there, let’s just say I was pretty disappointed. No…it was not because of my change in the yoke. You thought you had me there huh! These were the usual fitting issues that seem to happen every time with any pattern. The shoulders hung almost 2 inches over the ridge points, at chest level we needed to lose about 1 to 2 inches and the armpit area was full of extra fabric. “Awe crap” were naturally my first words. So then I made him try on his RTW shirt and discovered almost the same problems. I had a revelation! Besides the fact that I am finally figuring out fitting problems and recognizing them easily, more importantly, men have become comfortable wearing crappy fitted shirts!

This is where the bonding thing was suppose to be happening between me and my son but from his perspective, I think there is a bit of confusion. I think he is thinking, it fits him just fine so why not make the shirt and be done with it. I on the other hand want to make him the best shirt he could ever have. It’s a stale mate… a Mars vs Venus! So he walked off, thinking about cars, girls, making videos, drinking a beer.. whatever guys think about, and I did the only thing I could think of… I asked the Oracle (the internets!) what she knew about shirtmaking.

I learned quite a bit during my visit to the Oracle. There are some pretty nifty bloggers on the internets who share a wealth of information about shirtmaking.

Peter Lappin, of Malepatternboldness.blogspot.com is a very interesting gent whose blog I will continue to enjoy reading. He talked about felling seams when shirtmaking, totally groovy information that I hadn’t even thought of!

Pamela Erny, a custom shirtmaker who shared her split cowel collar design on her blog site, Off-the-cuff-style.blogspot.com that I can’t wait to try.

Geoffrey Edwards, blog writer who posts on the BurdaStyle.com forum website under the name, gedwoods. To my delight, one of his postings I found on the forum was “Drafting The Men’s Shirt Block”. Interestingly, he is a Canadian scientist with such a passion for sewing that for the past five years has developed and designed a new clothing line, “g-moda“. Last night I drafted a shirt for my son using this gentleman’s drafting instructions and it turned out quite well visibly. The next test of course will be to make a muslin.

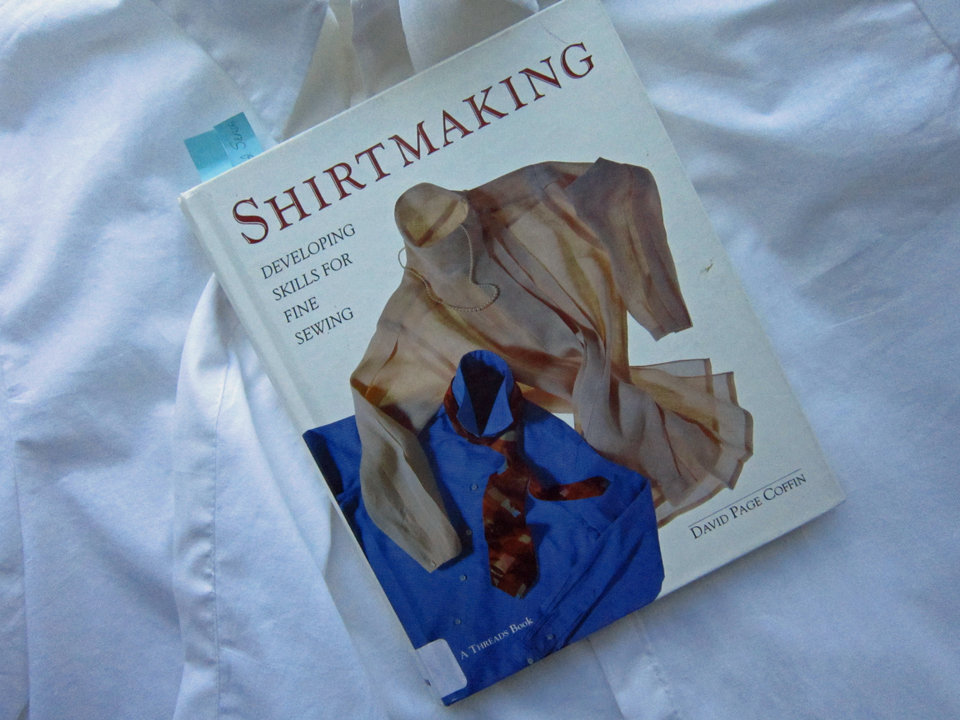

And last but not least, David Page Coffin, author of “Shirtmaking”. His book was recommended in a number of the shirtmaking blog articles I have read.

The beauty of this book discovery was that day-before-yesterday, while perusing the sewing book section in my local library not expecting to find much of anything, I stumbled across this very book! What a wealth of information. It’s so awesome that I have been reading it like a novel! It’s gonna be another one of my sewing library requirements! What’s more…he walks you through his draping technique, step-by-step, in the creating of a shirt, on a real man! You know what this means don’t you. I have briefed Jared of my intentions and noted a rather grim look on his face. There is no doubt in my mind that a six-pack of Newkie Brown Ale will appease his concerns and sweeten the deal! There will be an up-date soon on my shirtmaking career including the live male draping. Almost forgot to mention, straight pins will be involved!

Salute! Jessica

Read MoreDraping Fashion Designs

Some fabulous ladies to drape with!

Well…I have finished all my draping classes and learned right from the get-go that my biggest challenge was overcoming the feeling that I was wasting fabric. I am not a hard core recycle queen, not even remotely close, but as we cut, tore and marked our muslin and rayon for all the different projects we did, I had a struggle going on in my mind. Kinda weird, I know. Maybe this was in part due to the fact that at times it’s hard for me to find the extra funds to purchase fabric for my own sewing projects so to use up almost 14 yards of muslin and rayon for these classes gnawed on me. I had to keep reminding myself of what I was gaining in this process and believe me, I truly gained a lot!

To start off, let me first officially introduce you to “Wolfee”. Her and I worked quite well together. Since she is almost exactly my size, this means that everything I draped, with a few small adjustments, I will be able to use to make garments for myself. Pretty cool eh!

She is wearing black soutache braid for style lines.

Our instructor, Catherine Stephenson, Custom Couture Clothing, was awesome. She shared a wealth of information as she walked us through our draping projects, providing both group and individual guidance.

Catherine showing us how to drape a cowl neck.

Some of the draping techniques Catherine used were from the book, “The Art of Fashion Draping” by Connie Amaden-Crawford, a designer for The McCall Pattern Company under the Butterick label. It’s a bit spendy but will certainly be part of my sewing library one day soon.

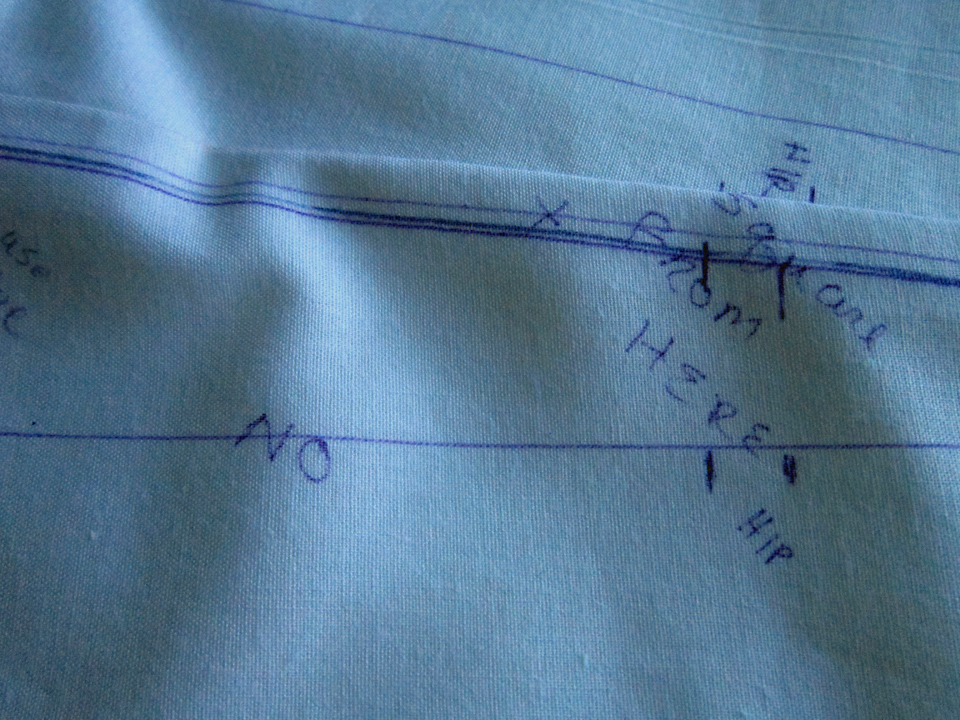

In the first session of classes, we learned the importance of grain lines and cross-grain lines since these play a major role in the draping process. Another crucial part of draping is being precise and consistent when marking the draped and pinned muslin pieces since these markings are the lines, notches and bust, waist and hip levels that we rely on to construct the garment. The learning curve started flattening real fast for most of us with this part of the draping process. It’s kind of difficult to take pieces of fabric off of a dress form and then pin them together to form a garment if you can’t figure out what your markings mean!

I think our Christian Dior jacket was one of our high points in our draping projects. After finishing, I knew where I should have been a bit more careful in my draping, but nonetheless, I think that if I can fix a few discrepancies, it could serve as a functional pattern to make a jacket for myself…aside from the crappy collar. I was not happy with it at all. It was a project we did earlier and I didn’t know that it was going to be what we would use for the collar of this jacket.

Princess bodice done and now making peplum.

Notice the batting around hp area. It was to ensure more fullness in the peplum.

Finished front of Christian Dior jacket with my crappy collar!

Back of Christian Dior jacket.

The final garment we draped was done on the bias! I have not worked much with bias though have been wanting to. I didn’t realize the complexity of just what happens when you cut fabric diagonally. Sheesh! One thing for sure, I will definitely have plenty of stay tape of some sort on hand when I create a bias garment

A cowl Neck

And the potential dress with a cowl neck

So guess what? Draping is a dying art. Many accredited fashion schools have removed draping from their fashion design programs because they feels it’s an obsolete technique. Since much of the design work these days is taken from drawings to computer pattern design programs, I guess technology is draping’s downfall. And get this…the ability to sew is not considered a requirement of a fashion designer. If you are talented enough to be able to design, you leave the sewing to someone else. Hmm… It sounds to me like being able to construct a garment through sewing is not considered very honorable let alone glamorous. Right about now I bet you can feel a rant coming on cuz I sure do!

Well I suppose I better show you that my draping classes were successful in showing me how to drape. If you are a returning visitor, you have seen a picture of some pastel green fabric with embroidered pink polka-dots. If this is your first visit, well…I used this fabric to make the princess-seam line dress that we draped in one of our classes and here it is.

I wore this to one of our last draping classes since Catherine had challenged me to make it and I knew I couldn’t chicken out. I felt a lot of sweating going on when she said take your sweater off and let me see. Fortunately this was not a full fledged test, but if it had been, from the smile on her face, I think I might have got an “A”.

Salute! Jessica

Read More

Portland, Oregon,

Portland, Oregon,